Customized injection moulding might be a specialised technique that enables manufacturers to provide plastic pieces and parts meant to meet up with particular specifications. Not like regular injection moulding, which usually generates off-the-shelf objects, customized injection moulding is about adaptability, precision, and innovation. It’s suitable for enterprises that call for distinctive shapes, components, or features inside their solutions.

What Is Tailor made Injection Moulding?

Custom made injection moulding requires setting up a bespoke mould and picking correct supplies to create sections that are tailored towards your client’s technical specs. This method commences with an in depth style period, generally making use of Personal computer-Aided Design and style (CAD) software program, then the fabrication of the personalized tool or die. After the mould is made, molten plastic is injected into it pressurized, forming a singular factor that matches the seem just.

Great things about Custom Moulding

The principal excellent point about custom made injection moulding could possibly be the means to make remarkably specialised parts. No matter whether it’s an advanced form, an honest tolerance, or perhaps a precise materials need, this technique can supply benefits that off-the-shelf elements are not able to match. It also offers large repeatability, ensuring Each and every element is regular in excellent and pleasure.

Customized moulding can even be scalable. As soon as the Original mould is produced, You need to use it to create thousands or perhaps plenty of similar elements successfully. This makes it a cost-productive Option for extensive-phrase creation, whether the upfront tooling expenses are greater.

Purposes in Sector

Customized injection moulding is used across many industries, including automotive, health-related, electronic products, and industrial equipment. Such as, a health care product company might call for a plastic casing with designed-in antimicrobial Houses, though an automotive company might have higher-power elements resistant to heat and chemical compounds.

Content Possibilities

Another very good factor about tailor made injection moulding could be the wide array of materials available. From rigid ABS and impression-resistant Polycarbonate check here to flexible TPU and chemical-resistant Nylon, consumers can choose the plastic that most carefully fits their application.

Partnering with Gurus

Working owning an seasoned injection moulding business like Australian Consolidated Plastics makes certain that every phase—from layout and prototyping to tooling and creation—is handled with knowledge. Their functionality to supply end-to-close help helps consumers reduce growth a while to deliver products to showcase quicker.

Summary

Personalized injection moulding is really a strong production Alternative that provides precision, adaptability, and effectiveness. No matter whether for prototyping or massive-scale creation, it permits businesses to produce progressive Strategies into large-top quality plastic products and solutions tailored with their precise demands.

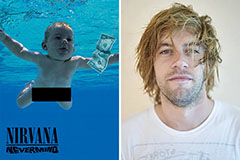

Spencer Elden Then & Now!

Spencer Elden Then & Now! Taran Noah Smith Then & Now!

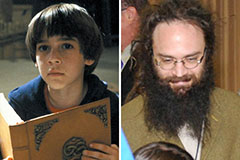

Taran Noah Smith Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now!